MIS (Management Information System)

Management Information System is a technology-driven system used to collect, store, and analyze data for better decision-making within an organization.

PREDICTIVE MAINTENACE

Predictive Maintenance is a proactive approach that uses real-time data to predict equipment failures before they happen. By monitoring key parameters like voltage, current, and operating time, it helps detect early signs of wear or malfunction. This reduces unplanned downtime, extends the lifespan of railway infrastructure, and lowers maintenance costs by addressing issues only when needed, ensuring smooth and safe operations.

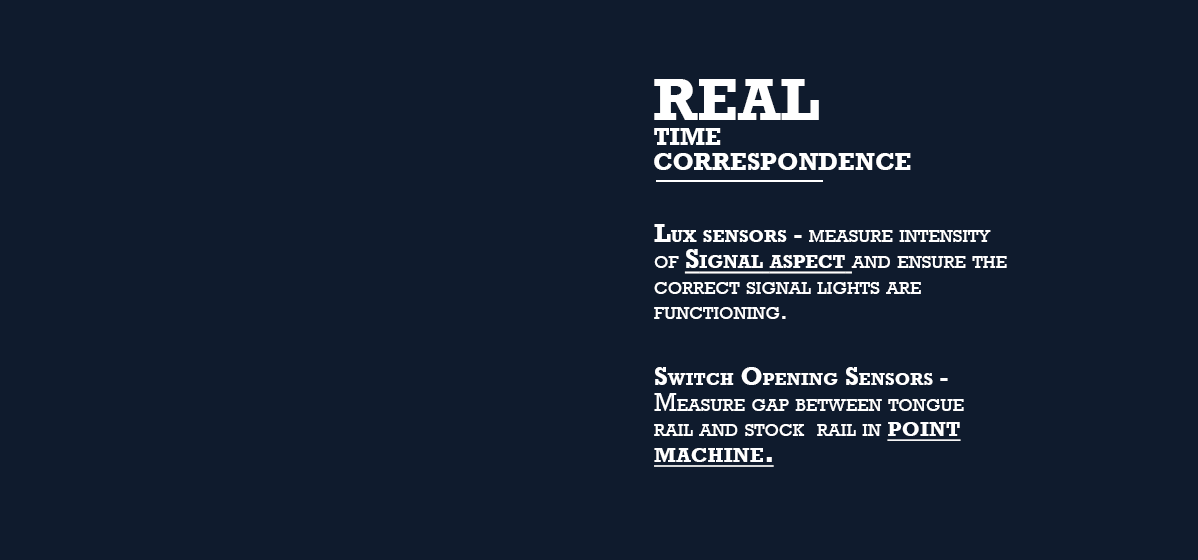

Real Time Correspondence

- Lux sensor- Measure intensity of signal aspect and ensure the correct signal lights are functioning.

- Switch opening sensors- Measure gap between Tongue rail and stock rail in point machine.

Generative AI

Upload your policy documents and ask our chatbot any question.

Get your answer within few seconds within the context.

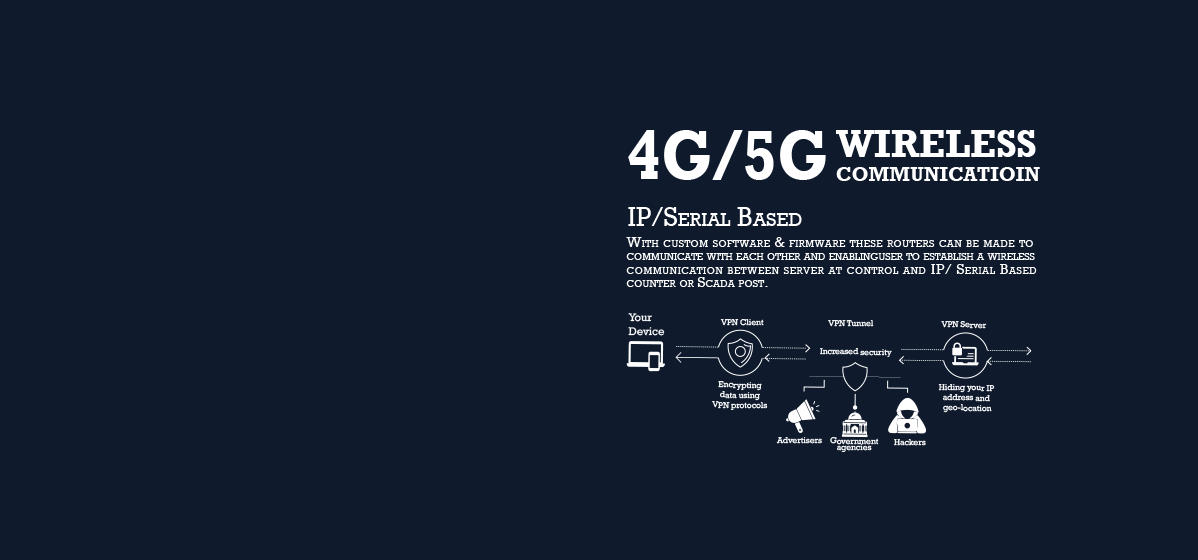

4G/5G Wireless Communication

With custom software & Firmware these routers can be made to communicate with each others and establish a wireless communication.

Who we are

Energy7 is a leading provider of IoT, Remote Diagnostics, and Predictive Maintenance solutions tailored specifically for Indian Railways. Our cutting-edge technology is designed to enhance the safety, efficiency, and reliability of railway operations across the country. We specialize in integrating advanced IoT sensors with existing railway infrastructure, enabling real-time monitoring of critical systems.

Our core strength lies in our AI and machine learning capabilities, which continuously analyze data from the field to detect anomalies and predict potential failures. By providing early alerts on any irregularities, our solutions help Indian Railways minimize downtime, reduce maintenance costs, and ensure the smooth functioning of trains and signaling systems.

Our innovative solutions are trusted by railway operators to deliver precise, actionable insights that improve asset management and enhance safety standards.

Features

Real-Time Condition Monitoring

Continuous monitoring of railway infrastructure in real-time, ensuring early detection of anomalies or performance issues.

AI-Driven Predictive Maintenance

Predictive algorithms anticipate equipment failures, allowing for maintenance planning before issues arise.

MIS Integration

Seamlessly integrated Maintenance Information System for tracking, scheduling, and managing maintenance tasks and historical records.

Safety Enhancements

Solutions that improve safety across the railway network by identifying and addressing potential risks before they cause failure.

Principles of our work

Innovation-driven

At ENERGY7, we push the boundaries of IoT, AI, and ML technologies to continuously develop and improve systems that elevate railway safety standards and operational performance.

Customer-centric Approach

Our focus is on creating customized, scalable solutions that meet the unique needs of our clients, ensuring smooth integration with existing infrastructure while addressing specific safety concerns.

Proactive Problem Solving

We aim to anticipate and prevent issues through advanced predictive maintenance and condition monitoring, ensuring safety and minimizing disruptions in railway operations.

Who we are

Features

Principles of our work

Who we are

Energy7 is a leading provider of IoT, remote diagnostics, and predictive maintenance solutions tailored specifically for Indian Railways. Our cutting-edge technology is designed to enhance the safety, efficiency, and reliability of railway operations across the country. We specialize in integrating advanced IoT sensors with existing railway infrastructure, enabling real-time monitoring of critical systems.

Our core strength lies in our AI and machine learning capabilities, which continuously analyze data from the field to detect anomalies and predict potential failures. By providing early alerts on any irregularities, our solutions help Indian Railways minimize downtime, reduce maintenance costs, and ensure the smooth functioning of trains and signaling systems.

Features

Real-Time Condition Monitoring:- Continuous monitoring of railway infrastructure in real-time, ensuring early detection of anomalies or performance issues.

AI-Driven Predictive Maintenance:– Predictive algorithms anticipate equipment failures, allowing for maintenance planning before issues arise.

MIS Integration:– Seamlessly integrated Maintenance Information System for tracking, scheduling, and managing maintenance tasks and historical records.

Safety Enhancements:- Solutions that improve safety across the railway network by identifying and addressing potential risks before they cause failure.

Principles of our work

Transparency

Top quality

Client Happiness

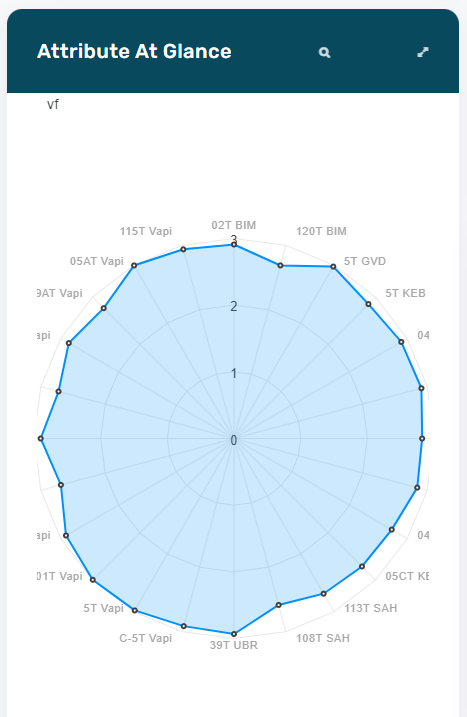

Attribute at glance

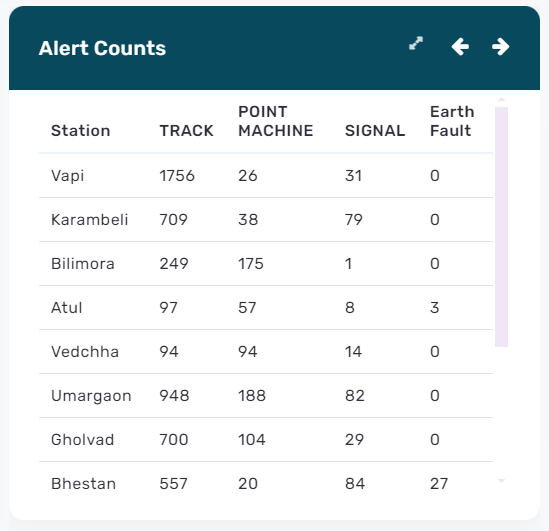

Alert counts

Site vs Alerts

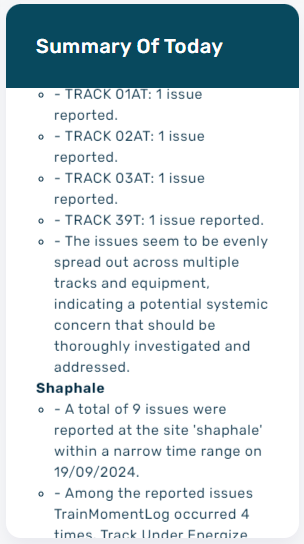

Summary of Today

why we are the best

Real time correspondence

Predictive maintenance

MIS (Management informaion sysytem)

Generative AI

4G/5G Wireless communication

Our Alerts based on AI & ML

Recent news & events

Our Imprint on Progress

Our commitment to innovation and excellence has enabled us to successfully connect 120+ Indian Railway Stations with advanced IoT, AI-powered predictive maintenance, and real-time monitoring solutions.

Our solutions are deployed across multiple railway zones, ensuring smooth, safe, and efficient train operations from North-Central Railway in Prayagraj to the Southern Railway in Chennai, and everywhere in between. Each location benefits from smarter maintenance strategies, proactive diagnostics, and cutting-edge technology designed to minimize downtime and improve the safety and reliability of railway networks.

With our innovative technology, we are committed to driving Indian Railways toward a future where maintenance is smarter, journeys are safer, and operations are uninterrupted.